Welcome to discuss your project requirements.

Welcome to discuss your project requirements.

Biomass two-layer continuous drum carbonization machine is a special carbonization equipment which can carbonize coconut shell, walnut shell, apricot shell, hemp pole, sawdust, sawdust, rice husk, bamboo, eucalyptus, mushroom residue, medicine residue, furfural residue, coffee residue, palm shell.

Biomass two-layer continuous drum carbonization machine is a special carbonization equipment which can carbonize coconut shell, walnut shell, apricot shell, hemp pole, sawdust, sawdust, rice husk, bamboo, eucalyptus, mushroom residue, medicine residue, furfural residue, coffee residue, palm shell.

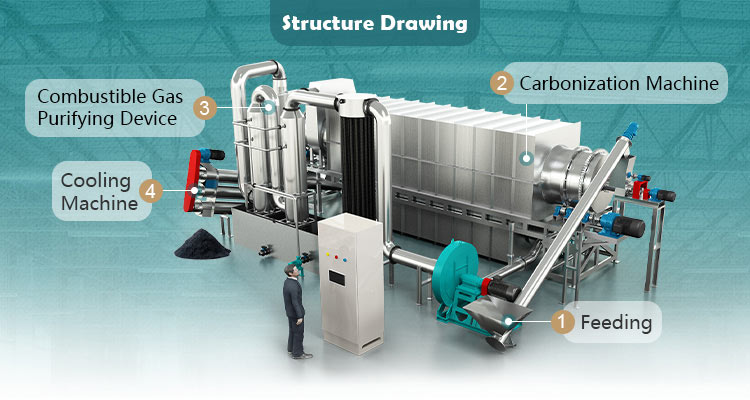

The biomass two-layer continuous drum carbonization machine is a professional equipment for continuous high-temperature heating and carbonization of biomass under anaerobic and oxygen-poor conditions. It consists of a two-layer carbonization machine, a pre-burner (or gasification furnace), and combustible gas purification It consists of device, external heating furnace of carbonization machine, feeding conveyor, cooling carbon machine and control. The biomass is transported by the conveyor into the inner drum. The waste heat in the furnace is used to dry and preheat the material to 200-250°C. It then enters the outer drum for high-temperature carbonization. There is a combustible gas recovery pipe at the end of the outer drum to complete the carbonization process. The CO, CH₄, C₂H₆ and other gases produced in the flue gas purification system separate the wood tar, wood acid liquid, water and ash substances to obtain pure combustible gas. The wind is sent to the external heating furnace of the carbonization machine, fully burned, and heated to the carbonization machine. , to achieve the purpose of reciprocating heating, carbonization, and continuous production. The carbonized product is discharged through a water-cooled charcoal discharge machine, and the carbonization ignition is supplied with heat by a preheating burner (or gasification furnace).

| Model | Inner layer diameter(mm) | Outer layer diameter(mm) | The drum length(m) | Carbon capacity(kg/h) | Dimension(m) |

| JTTJ1410/2 | 800 | 1400 | 10 | 300-500 | 10.0*2.1*2.8 |

| JTTJ1610/2 | 1000 | 1600 | 10 | 500-700 | 10.0*2.3*3.0 |

| JTTJ1810/2 | 1200 | 1800 | 10 | 700-1000 | 10.0*2.6*3.2 |

| JTTJ2010/2 | 1400 | 2000 | 10 | 1100-1300 | 10.0*2.9*3.9 |

| JTTJ2312/2 | 1600 | 2300 | 12 | 1500-2000 | 12.0*3.2*4.2 |

| JTTJ2512/2 | 1800 | 2500 | 12 | 2200-2500 | 12.0*3.5*4.5 |

| JTTJ2912/2 | 2200 | 2900 | 12 | 2700-3000 | 12.0*3.9*4.9 |

| JTTJ3212/2 | 2500 | 3200 | 12 | 3300-3800 | 12.0*4.2*5.3 |

| JTTJ3612/2 | 2900 | 3600 | 12 | 4000-4500 | 12.0*4.6*5.8 |

Capacity: 2t/h

Location: Malaysia

Configuration: as biochar

Capacity: 300kg/h

Location: Korea

Configuration: as biochar

Capacity: 2.5 t/h

Location: Russia

Configuration: Recycled Aluminum

According to the customer's actual requirements, raw materials and use of customized solutions

Own production base, strict production standards and processes, professional quality control.

Engineers track the entire service, install and commissioning the equipment to ensure successful operation.

Provide technical support, technical service, technical training, after-sales service.