Welcome to discuss your project requirements.

Welcome to discuss your project requirements.

Biomass Pellets Torrefaction Machine is developed to convert densified “white” biomass pellets into “black” torrefied pellets. The complete torrefaction plant is designed and built by our company, while the torrefaction reactor and the process adopt the patented technology from our strategic partner. The technology provides the opportunity to torrefy “white” biomass pellets directly with minimal dust and small particles, thus safeguarding the quality of torrefied “black” pellets to meet international standard, while optimizing the overall energy consumption of the complete plant.

We have a design and research team that leverages the newest technologies to bring compact and highly convenient solutions to a wide range of users.

Our unique design and compact torrefied pellet machine can help you torrefy your white biomass pellets without causing significant pollution. This makes our machines eco-friendly and meets the global standards in terms of pellets and machine quality. Our machines also consume comparatively low energy.

Superior Performance of Torrefied Wood PelletsWith a higher energy density, less water content, pure composition, torrefied wood pellet has a lot of advantagescomparing with wood pellets and even coal.

1. With a higher energy density, torrefied wood pellets performs more efficiently than common wood pellets inpower plant to replace coal.

2. With less water content, it is not easy to get damp, thus to save longer.

3. Torrefied wood pellet is a carbon neutral product. No polluting gases is be released during its burning.

4. After torrefied, biomass materials turn out to have a higher grindability index and they are easier to pelletizeby biomass pellet mill.

5. More dense, the shipping cost of torrefied wood pellets is less than that of wood pellets.

Biomass Pellets Torrefaction furnace is suitable for carbonization of Biomass Pellets and agricultural biomass. Such as sawdust, wood chips, bagasse, coffee grounds, bamboo, coconut shell, cherry shell, date, walnut shell, apricot shell, peanut shell, rice husk, cotton,etc.

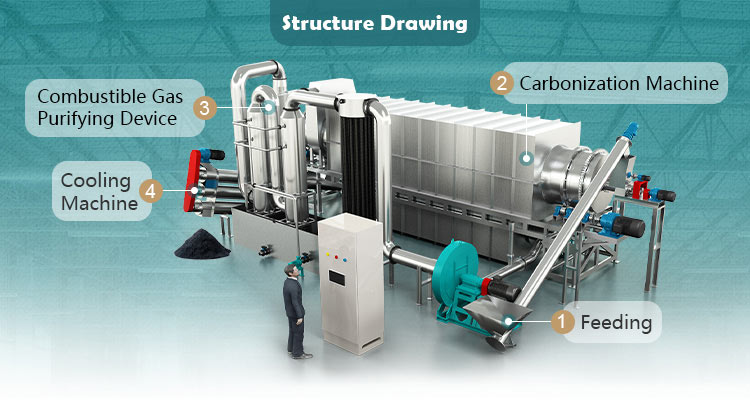

It consists of torrefaction reactor (without counting the upper and lower hoppers), a white biomass pellets feeding system, a hot gas distribution system, a heating system, a cooling system and an Artificial Intelligence (AI) powered process control system with internet access.

| Model | Diameter(mm) | The drum length(m) | Carbon capacity(kg/h) | Drum speed(rpm) | Dimension(m) |

| JTTJ1010 | 1000 | 10 | 100-200 | 1.5-2.5 | 10.0*1.7*2.8 |

| JTTJ1210 | 1200 | 10 | 200-300 | 1.5-2.5 | 10.0*2.0*3.0 |

| JTTJ1410 | 1400 | 10 | 400-500 | 1.5-2.5 | 10.0*2.2*3.2 |

| JTTJ1612 | 1600 | 12 | 600-800 | 2.0-3.0 | 10.0*2.4*3.5 |

| JTTJ1912 | 1900 | 12 | 900-1100 | 2.0-3.0 | 12.0*2.8*3.8 |

| JTTJ2212 | 2200 | 12 | 1200-1500 | 2.0-3.0 | 12.0*3.2*4.2 |

| JTTJ2512 | 2500 | 12 | 1600-2000 | 2.0-3.0 | 12.0*3.5*4.5 |

| JTTJ3012 | 3000 | 12 | 2200-2600 | 2.0-3.0 | 12.0*4.0*5.0 |

| JTTJ3612 | 3600 | 12 | 3000-3800 | 2.0-3.0 | 12.0*4.6*5.6 |

Capacity: 2t/h

Location: Malaysia

Configuration: as biochar

Capacity: 300kg/h

Location: Korea

Configuration: as biochar

Capacity: 2.5 t/h

Location: Russia

Configuration: Recycled Aluminum

According to the customer's actual requirements, raw materials and use of customized solutions

Own production base, strict production standards and processes, professional quality control.

Engineers track the entire service, install and commissioning the equipment to ensure successful operation.

Provide technical support, technical service, technical training, after-sales service.