Welcome to discuss your project requirements.

Welcome to discuss your project requirements.

Activated carbon regeneration furnace refers to the use of physical or chemical methods to remove the adsorbate adsorbed on the activated carbon and restore its adsorption performance without destroying the original structure of the activated carbon, so as to achieve the purpose of repeated use. Modified activated carbon materials are widely used in the field of sewage treatment, and have increasingly shown their attractive prospects in the treatment of water environmental pollution.

Coal-based raw materials,Wood-based raw materials,Coconut shell/fruit shell raw materials,Bamboo-based raw materials,Straw-based raw materials,etc

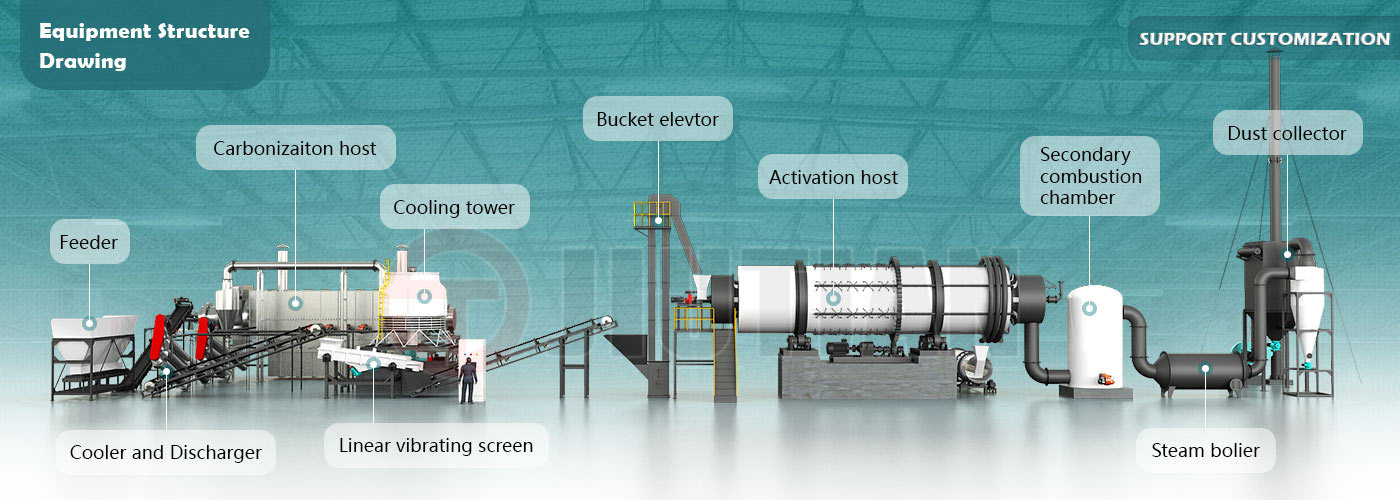

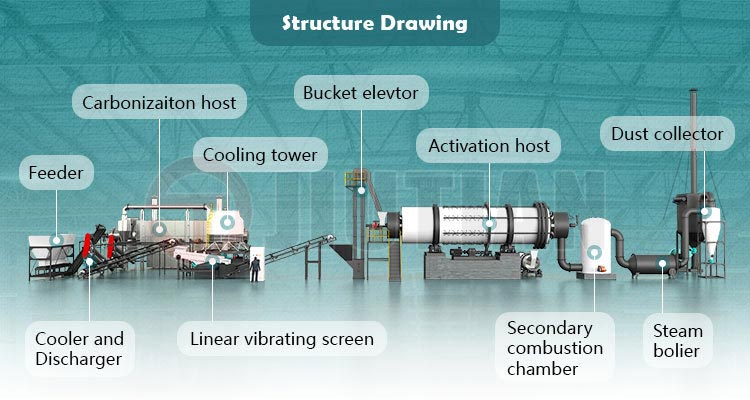

The overall production line reflects the general principles of advanced, efficient, stable, energy-saving, environmentally friendly, safe, frugal and reasonable.The main equipment uses matching drum carbonization machine, drum activation machine and feeding device, conveying device, combustible gas purification device, cooling carbonization device, PLC control system to form the layout of the carbonization activation production line.

Carbonization production line includes silo, conveying equipment, carbonization host, combustible gas purification equipment, dust removal equipment and cooling carbonization equipment.

Activation production line includes screening equipment, conveying equipment, activation host, waste gas treatment and recovery system, dust removal system and PLC control system.

| Model | Output (kg/h) | Drum diameter (m) | Roller length (m) | Overall dimensions (m) | Output ratio (%) |

|---|---|---|---|---|---|

| JTACM-100 | 80-100 | 1.9 | 14 | 15.2*2.2*2.6 | 2.2-2.5:1 |

| JTACM-150 | 120-150 | 2.2 | 15 | 16.3*2.6*3.1 | 2.2-2.5:1 |

| JTACM-200 | 170-200 | 2.5 | 15 | 16.5*3.0*3.5 | 2.1-2.5:1 |

| JTACM-300 | 250-300 | 2.8 | 15 | 16.5*3.4*4.0 | 2.1-2.5:1 |

| JTACM-400 | 320-400 | 3.2 | 15 | 16.6*3.8*4.4 | 2.1-2.5:1 |

| JTACM-500 | 430-540 | 3.6 | 15 | 16.6*4.2*4.8 | 2.1-2.5:1 |

Capacity: 2t/h

Location: Malaysia

Configuration: as biochar

Capacity: 300kg/h

Location: Korea

Configuration: as biochar

Capacity: 2.5 t/h

Location: Russia

Configuration: Recycled Aluminum

According to the customer's actual requirements, raw materials and use of customized solutions

Own production base, strict production standards and processes, professional quality control.

Engineers track the entire service, install and commissioning the equipment to ensure successful operation.

Provide technical support, technical service, technical training, after-sales service.