Welcome to discuss your project requirements.

Welcome to discuss your project requirements.

A rotary kiln refers to a rotating calcining kiln (commonly known as a rotary kiln), which belongs to the category of building materials equipment. Rotary kilns can be divided into cement kilns, metallurgical chemical kilns and lime kilns according to the different materials they process. Cement kilns are mainly used to calcine cement clinker, and are divided into two categories: dry-process cement kilns and wet-process cement kilns. Metallurgical chemical kilns are mainly used in the metallurgical industry for magnetization roasting of lean iron ore in steel plants; oxidation roasting of chromium and nickel iron ores; roasting of high-alumina vanadium ore in refractory plants and roasting of clinker and aluminum hydroxide in aluminum plants; and roasting of chromium ore sand and chromium ore powder and other minerals in chemical plants. Lime kilns (i.e., active lime kilns) are used to roast active lime and light-burned dolomite for use in steel plants and ferroalloy plants.

cement, lime, refractories, metakaolin, titanium dioxide, alumina, vermiculite, iron ore pellets. Rotary kilns are also used to roast various sulfide ores prior to metal extraction.

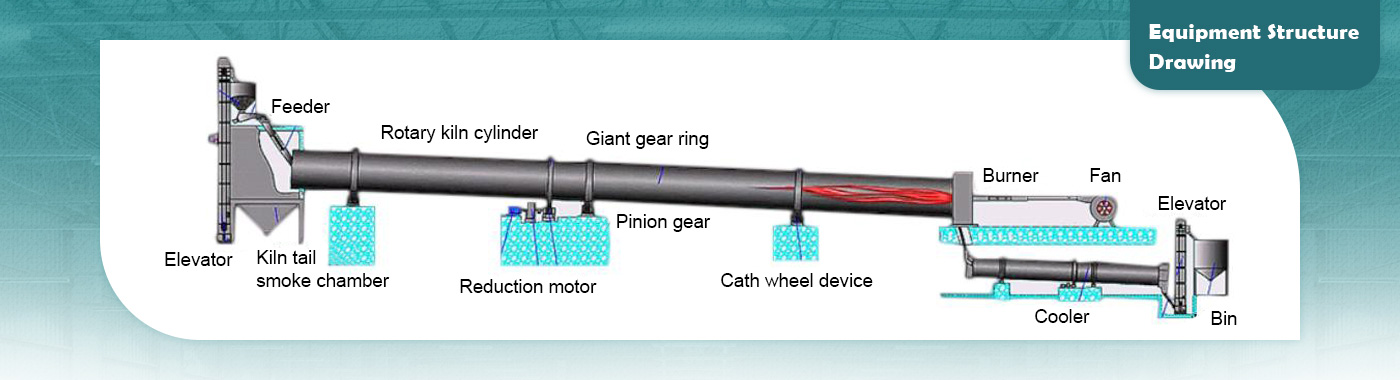

The cylinder of the lime rotary kiln is made of rolled steel plates and lined with refractory materials. It is inclined at a specified angle to the horizontal line and supported by multiple sets of riding rings on various supporting devices. The main drive motor transmits power to the open gear device through the main reducer, driving the rotary kiln. Materials enter the kiln for calcination from the kiln tail (the high end of the cylinder). Due to the inclination of the cylinder and the slow rotation, the materials roll along the circumference and move axially (from the high end to the low end), continuing their process, and finally, the finished product enters the cooler through the kiln head hood for cooling. Fuel is injected into the kiln from the kiln head, and after exchanging heat with the materials, the waste gas is discharged from the kiln tail.

1. High temperature/cleanliness: Our specially made kiln core cylinder effectively inhibits oxidation and wear under high temperature conditions, maintains a clean atmosphere, and prevents product contamination.

2. Special atmosphere gas: The original sealing system ensures the airtightness of the kiln, thereby realizing special atmosphere gas heating.

3. High temperature control accuracy: The original temperature measurement system can measure the actual temperature of the material and achieve high-precision temperature control.

4. Advanced dust removal technology and exhaust gas treatment device: Committed to reducing smoke and exhaust gas emissions and achieving more environmentally friendly production. Our products not only meet production needs, but also shoulder environmental responsibility.

| Equipment | Diameter(m) | Length(m) | Slope(%) | Output(t/d) | Speed (r/min) | Power(kw) | Total Weight (kg) |

|---|---|---|---|---|---|---|---|

| Φ2.5×30 | 2.5 | 30 | 3.5 | 50 | 0.42-2.35 | 55 | 115 |

| Φ2.5×36 | 2.5 | 36 | 3.5 | 100 | 0.5-1.54 | 55 | 132 |

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 201.94 |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| Φ3.0×60 | 3 | 60 | 4 | 800 | 0.3-2 | 100 | 310 |

| Φ3.2×50 | 3 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.26-2.66 | 125 | 283 |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.39-3.96 | 315 | 510 |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.39-3.96 | 375 | 583 |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710 |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.39-3.96 | 630 | 899 |

| Φ5.0×74 | 5.0 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | max4.23 | 800 | 1265 |

Capacity: 2t/h

Location: Malaysia

Configuration: as biochar

Capacity: 300kg/h

Location: Korea

Configuration: as biochar

Capacity: 2.5 t/h

Location: Russia

Configuration: Recycled Aluminum

According to the customer's actual requirements, raw materials and use of customized solutions

Own production base, strict production standards and processes, professional quality control.

Engineers track the entire service, install and commissioning the equipment to ensure successful operation.

Provide technical support, technical service, technical training, after-sales service.