Welcome to discuss your project requirements.

Welcome to discuss your project requirements.

The Continuous Azolla Biochar Machine is equipment that carbonizes Azolla under high temperature conditions in a carbonization machine.

By carbonizing Azolla feedstock with the biochar machine, biochar with high fixed carbon content and a low H/Corg ratio is obtained. This biochar can be used for carbon credit applications and mixed with animal manure, such as cow dung, to produce biochar-based fertilizer pellets, generating two sources of income.

Azolla,sawdust, wood chip, bagasse, coffee grounds, bamboo, coconut shell, cherry shell, jujube, walnut shell, apricot shell, peanut shell, rice husk, cotton stalk, straw, eucalyptus, mushroom residue, medicine residue, furfural residue,coffe,etc.

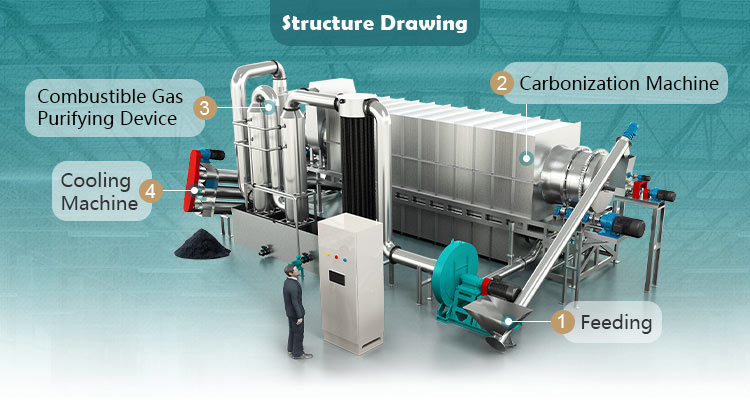

Azolla carbonization machine is a device that heats and azolla or other biomass materials under oxygen-free conditions to produce biochar, combustible gas, etc.

The Azolla Biochar Machine consists of equipment such as a conveyor, main drum, dust removal system, purification system, burner, and distribution cabinet. It adopts an upper-lower layer design, significantly improving drying and carbonization efficiency. This newly developed continuous carbonization equipment integrates high efficiency, environmental protection, and intelligence.

The high-quality Azolla biochar produced has a high fixed carbon content and an H/Corg ratio of <0.2, meeting the highest quality standards of Puro Earth.

The entire production line can also be equipped with a mixer, pellet machine, and pellet drying machine, allowing the produced biochar-based organic fertilizer pellets to be directly packaged and sold.

| Model | Diameter(mm) | The drum length(m) | Carbon capacity(kg/h) | Drum speed(rpm) | Dimension(m) |

| JTTJ1010 | 1000 | 10 | 100-200 | 1.5-2.5 | 10.0*1.7*2.8 |

| JTTJ1210 | 1200 | 10 | 200-300 | 1.5-2.5 | 10.0*2.0*3.0 |

| JTTJ1410 | 1400 | 10 | 400-500 | 1.5-2.5 | 10.0*2.2*3.2 |

| JTTJ1612 | 1600 | 12 | 600-800 | 2.0-3.0 | 10.0*2.4*3.5 |

| JTTJ1912 | 1900 | 12 | 900-1100 | 2.0-3.0 | 12.0*2.8*3.8 |

| JTTJ2212 | 2200 | 12 | 1200-1500 | 2.0-3.0 | 12.0*3.2*4.2 |

| JTTJ2512 | 2500 | 12 | 1600-2000 | 2.0-3.0 | 12.0*3.5*4.5 |

| JTTJ3012 | 3000 | 12 | 2200-2600 | 2.0-3.0 | 12.0*4.0*5.0 |

| JTTJ3612 | 3600 | 12 | 3000-3800 | 2.0-3.0 | 12.0*4.6*5.6 |

Capacity: 2t/h

Location: Malaysia

Configuration: as biochar

Capacity: 300kg/h

Location: Korea

Configuration: as biochar

Capacity: 2.5 t/h

Location: Russia

Configuration: Recycled Aluminum

According to the customer's actual requirements, raw materials and use of customized solutions

Own production base, strict production standards and processes, professional quality control.

Engineers track the entire service, install and commissioning the equipment to ensure successful operation.

Provide technical support, technical service, technical training, after-sales service.