Welcome to discuss your project requirements.

Welcome to discuss your project requirements.

This biochar fertilizer line utilizes high-temperature pyrolysis technology to convert agricultural organic waste into high-value-added biochar fertilizer, achieving the recovery and utilization of combustible gases and the self-circulation of energy during the production process. The plant can operate continuously for extended periods, possessing core advantages such as zero pollution, zero emissions, low labor requirements, huge production capacity, and significant energy conservation and emission reduction, representing cutting-edge technology in the field of organic solid waste resource utilization.

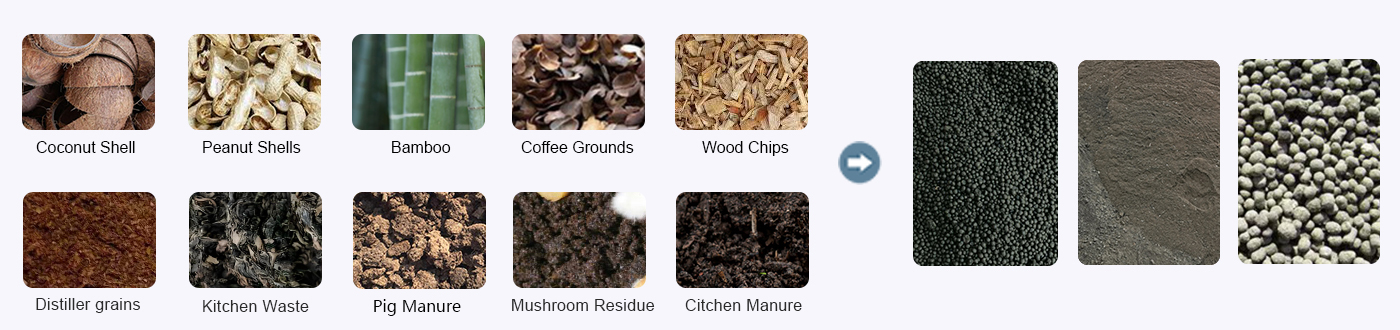

This biochar-based fertilizer production line is scientifically designed and widely compatible, suitable for the co-processing and fertilizerization of various organic and biomass raw materials. The materials used are diverse, mainly including two categories: first, raw materials for biochar preparation, such as agricultural residues like rice husks, wheat straw, and corn stalks; forestry processing waste such as sawdust, wood chips, and branches; and other biomass rich in lignin, such as coconut shells, bamboo chips, and fruit shells; second, raw materials for composting fermentation, such as livestock and poultry manure like chicken, pig, and cow manure; pre-treated kitchen waste or biogas residue; and biomass waste such as distiller's grains, vinegar residue, mushroom residue, and traditional Chinese medicine residue. By co-processing these two major categories of materials, this production line enables the efficient resource utilization of agricultural, forestry, and urban/rural organic waste.

1.It improves soil structure, overcomes continuous cropping obstacles, and enhances water and fertilizer retention capacity; it solidifies and passivates the activity of heavy metals in the soil; it promotes root development and activates soil microorganisms.

2.It possesses the dual advantages of organic and inorganic fertilizers, improving fertilizer utilization; effectively reducing chemical fertilizer use; and increasing the yield and quality of agricultural products, with some products meeting organic standards.

3.The equipment is safe, environmentally friendly, stable in operation, and has a long service life. It utilizes numerous new materials and processes, adopts patented technology design, and undergoes precision production. After extensive practical testing, every detail is perfected to ensure the quality of each set of equipment.

The entire biochar-based fertilizer production line begins with the carbonization of biomass raw materials. Biomass is carbonized at high temperatures using a carbonization machine to produce biochar. Subsequently, a biochar crusher breaks down the carbonized biochar to increase its specific surface area and reactivity. Simultaneously, compost raw materials undergo fermentation and maturation using a compost turning machine, ensuring thorough mixing and aeration of the compost material to promote the decomposition and stabilization of organic matter.The processed biochar powder and matured compost are precisely batched in a batching silo and then uniformly mixed in a mixer. The mixed material is first finely pulverized in a crusher to ensure a fine texture, and then fed into a granulator where it is extruded under pressure and specific humidity to form granular fertilizer. Finally, the cooled finished product is weighed and packaged, completing the entire biochar-based fertilizer preparation process. This process integrates the carbon-fixing properties of biochar with the nutrient advantages of compost. The mixed material not only enriches soil nutrients but also enhances soil structure and fertility over time, achieving a combination of efficient resource utilization and green agricultural production.

| Model | Diameter(mm) | The drum length(m) | Carbon capacity(kg/h) | Drum speed(rpm) | Dimension(m) |

| JTTJ1010 | 1000 | 10 | 100-200 | 1.5-2.5 | 10.0*1.7*2.8 |

| JTTJ1210 | 1200 | 10 | 200-300 | 1.5-2.5 | 10.0*2.0*3.0 |

| JTTJ1410 | 1400 | 10 | 400-500 | 1.5-2.5 | 10.0*2.2*3.2 |

| JTTJ1612 | 1600 | 12 | 600-800 | 2.0-3.0 | 10.0*2.4*3.5 |

| JTTJ1912 | 1900 | 12 | 900-1100 | 2.0-3.0 | 12.0*2.8*3.8 |

| JTTJ2212 | 2200 | 12 | 1200-1500 | 2.0-3.0 | 12.0*3.2*4.2 |

| JTTJ2512 | 2500 | 12 | 1600-2000 | 2.0-3.0 | 12.0*3.5*4.5 |

| JTTJ3012 | 3000 | 12 | 2200-2600 | 2.0-3.0 | 12.0*4.0*5.0 |

| JTTJ3612 | 3600 | 12 | 3000-3800 | 2.0-3.0 | 12.0*4.6*5.6 |

Capacity: 2t/h

Location: Malaysia

Configuration: as biochar

Capacity: 300kg/h

Location: Korea

Configuration: as biochar

Capacity: 2.5 t/h

Location: Russia

Configuration: Recycled Aluminum

According to the customer's actual requirements, raw materials and use of customized solutions

Own production base, strict production standards and processes, professional quality control.

Engineers track the entire service, install and commissioning the equipment to ensure successful operation.

Provide technical support, technical service, technical training, after-sales service.