Welcome to discuss your project requirements.

Welcome to discuss your project requirements.

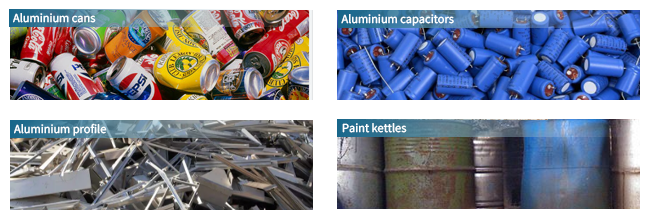

Waste cans are recycled and reused. Waste cans are thin in texture and large in surface area. They are severely oxidized and burned during the smelting process, and the metal recovery rate is low. There is a paint layer on the surface, which has a certain impact on the quality of aluminum alloy. Direct melting and easy to produce flue gas pollution. After being collected by waste recyclers, waste stations, and waste companies, the shape of waste cans is destroyed. Some have been packed into blocks, which are difficult to separate and pre-treatment is difficult.

How to fully recycle cans, the key process is how to remove the paint. The continuous carbonization furnace for cans provided by our company achieves good results by removing paint through the carbonization process.

Food cans: Aluminum cans used for packaging food products such as milk powder and luncheon meat.

Daily-use cans: Aluminum cans for daily chemical products such as spray cans and cosmetic cans.

Industrial waste: Defective products and scraps generated during the aluminum can manufacturing process.

The packaged, compressed or flattened cans are first processed into fragments of about 4 cm by a shredder, and then added to the drum of the continuous carbonization furnace through a spiral feeder. Because the furnace is almost a closed space, it meets the anaerobic conditions, so that the cans are pyrolyzed and carbonized at a temperature of more than 400 degrees inside the carbonization furnace. The generated flue gas passes through the recovery pipeline, the flue gas purification system, and then to the burner to heat the main furnace, achieving the effect of reciprocating heating and carbonization. During the initial carbonization preheating, the surface paint of the cans begins to carbonize and pyrolyze, and the pyrolysis produces combustible gas to achieve normal combustion, gas circulation combustion and no flue gas discharge. The normal production state, finally obtaining pure aluminum.

| Model | Inner layer diameter(mm) | Outer layer diameter(mm) | The drum length(m) | Carbon capacity(kg/h)) | Dimension(m) |

|---|---|---|---|---|---|

| JTTJ1410/2 | 800 | 1400 | 10 | 300-500 | 10.0*2.1*2.8 |

| JTTJ1610/2 | 1000 | 1600 | 10 | 500-700 | 10.0*2.3*3.0 |

| JTTJ1810/2 | 1200 | 1800 | 10 | 700-1000 | 10.0*2.6*3.2 |

| JTTJ2010/2 | 1400 | 2000 | 10 | 1000-1300 | 10.0*2.9*3.9 |

| JTTJ2312/2 | 1600 | 2300 | 12 | 1500-2000 | 12.0*3.2*4.2 |

| JTTJ2512/2 | 1800 | 2500 | 12 | 2200-2500 | 12.0*3.5*4.5 |

| JTTJ2912/2 | 2200 | 2900 | 12 | 2700-3000 | 12.0*3.9*4.9 |

| JTTJ3212/2 | 2500 | 3200 | 12 | 3300-3800 | 12.0*4.2*5.3 |

| JTTJ3612/2 | 2900 | 3600 | 12 | 4000-4500 | 12.0*4.6*5.8 |

Capacity: 2t/h

Location: Malaysia

Configuration: as biochar

Capacity: 300kg/h

Location: Korea

Configuration: as biochar

Capacity: 2.5 t/h

Location: Russia

Configuration: Recycled Aluminum

According to the customer's actual requirements, raw materials and use of customized solutions

Own production base, strict production standards and processes, professional quality control.

Engineers track the entire service, install and commissioning the equipment to ensure successful operation.

Provide technical support, technical service, technical training, after-sales service.