Welcome to discuss your project requirements.

Welcome to discuss your project requirements.

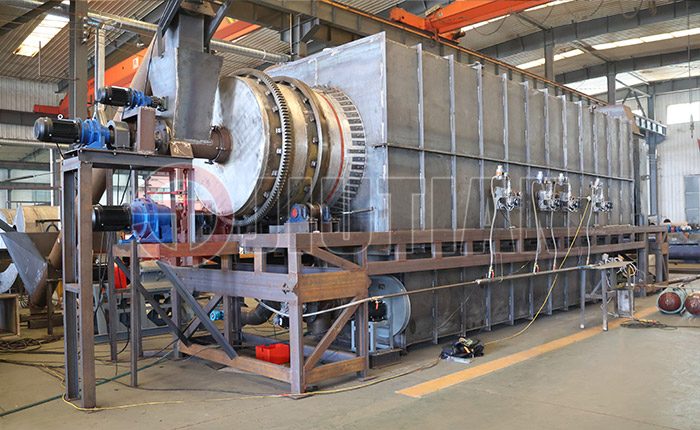

Continuous carbonization furnaces are usually used to carbonize various organic raw materials to prepare charcoal. The following are some common types of materials that can be carbonized in continuous carbonization furnaces:

1. Wood: This is the most common raw material, usually using hardwood (such as oak, beech, cherry wood) or cork (such as pine).

2. Coconut shell: Coconut shell is another commonly used raw material, suitable for preparing charcoal due to its high carbon content and hard shell.

3. Sawdust and sawdust: Sawdust and sawdust generated during woodworking or wood processing can be used as raw materials.

4. Fruit shell: Some fruit shells, such as olive shells, walnut shells, and nut shells, can be used to prepare charcoal.

5. Straw: Agricultural waste, such as rice straw, wheat straw, and corn straw, can also be carbonized into charcoal.

6. Pulp waste: The waste from the production process of pulp and paper usually contains wood fibers, which can be used to prepare charcoal.

7. Animal and plant waste: Some continuous carbonization furnaces can also handle animal and plant waste, such as animal grass, poultry manure, dead leaves, etc.

8. Biomass energy waste: This includes wooden biomass energy waste, such as wood particles, sawdust, sawdust, branches, etc., which can be used to produce charcoal.

9. Other organic materials: In principle, any organic material containing carbon can be carbonized into charcoal, but the quality and yield may vary.

Please note that the performance and parameters of continuous carbonization furnaces may vary depending on the type and nature of the raw materials. When selecting raw materials, it is necessary to consider the capacity of the carbonization furnace and the specific application requirements. In addition, for certain raw materials, pre-treatment may be necessary to ensure that they can produce high-quality charcoal during the carbonization process.