Welcome to discuss your project requirements.

Welcome to discuss your project requirements.

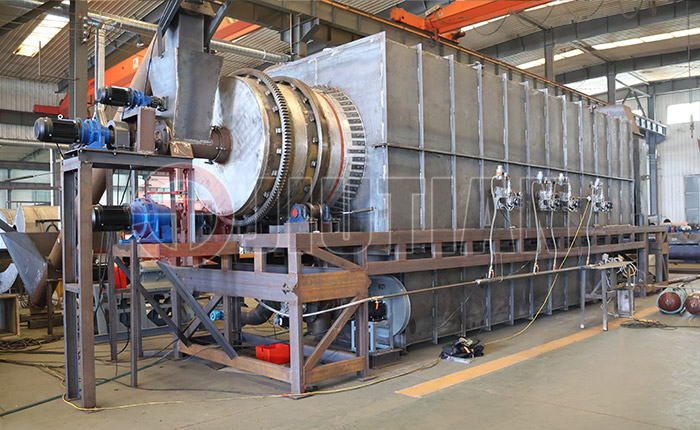

Continuous Pyrolysis Carbonization Furnace is a device used to convert organic raw materials into carbon, and its working principle involves the pyrolysis process in high temperature and low oxygen environments. The following are the basic steps of the working principle of a continuous pyrolysis and carbonization furnace:

1. Feed and pre-treatment: Organic raw materials (such as wood, bamboo, fruit shells, waste, etc.) are first fed into the feed system in the furnace. Before entering the carbonization furnace, the raw materials usually undergo some pre-treatment steps, such as removing impurities, cutting into appropriately sized blocks or particles.

2. High temperature heating: After the raw materials enter the carbonization furnace, the temperature inside the furnace is raised to a high temperature level (usually between 600 ° C and 900 ° C). Under this high-temperature environment, organic raw materials begin to undergo pyrolysis reactions, where the high temperature and low oxygen atmosphere cause the raw materials to decompose into gases, liquids, and residues.

3. Pyrolysis reaction: Pyrolysis is the main reaction process, in which the molecular structure of organic raw materials decomposes into carbon, tar, and gases (mainly some organic gases and water vapor) at high temperatures. Carbon is the final product, while tar and gas are by-products.

4. Gas separation: The generated gas is directed to the gas separation system, usually cooled and condensed to collect tar and liquid products. These products can be further processed or used for other purposes.

5. Carbon carbon cooling and emission: After the pyrolysis reaction, the generated carbon needs to be cooled to stop the carbonization process and prevent further combustion. Then, the cooled carbon can be continuously discharged from the carbonization furnace through the emission system.

6. Automation control: Continuous pyrolysis and carbonization furnaces are usually equipped with highly automated control systems that can monitor and adjust parameters such as temperature, oxygen supply, and feed rate to ensure the stability of the carbonization process and product quality. The automation system can also automatically adjust the feeding speed as needed to maintain continuous operation.

In summary, the working principle of a continuous pyrolysis and carbonization furnace involves pyrolysis of organic raw materials under high temperature and low oxygen atmosphere, decomposing them into carbon, tar, and gas. This process is continuous, with raw materials continuously entering the carbonization furnace from the feed end, while the generated carbon is continuously discharged from the discharge end, achieving a continuous operation of feeding while discharging. This type of equipment is usually used to prepare carbon products such as charcoal, bamboo charcoal, and activated carbon, and has the advantages of high efficiency and suitability for large-scale production.