Welcome to discuss your project requirements.

Welcome to discuss your project requirements.

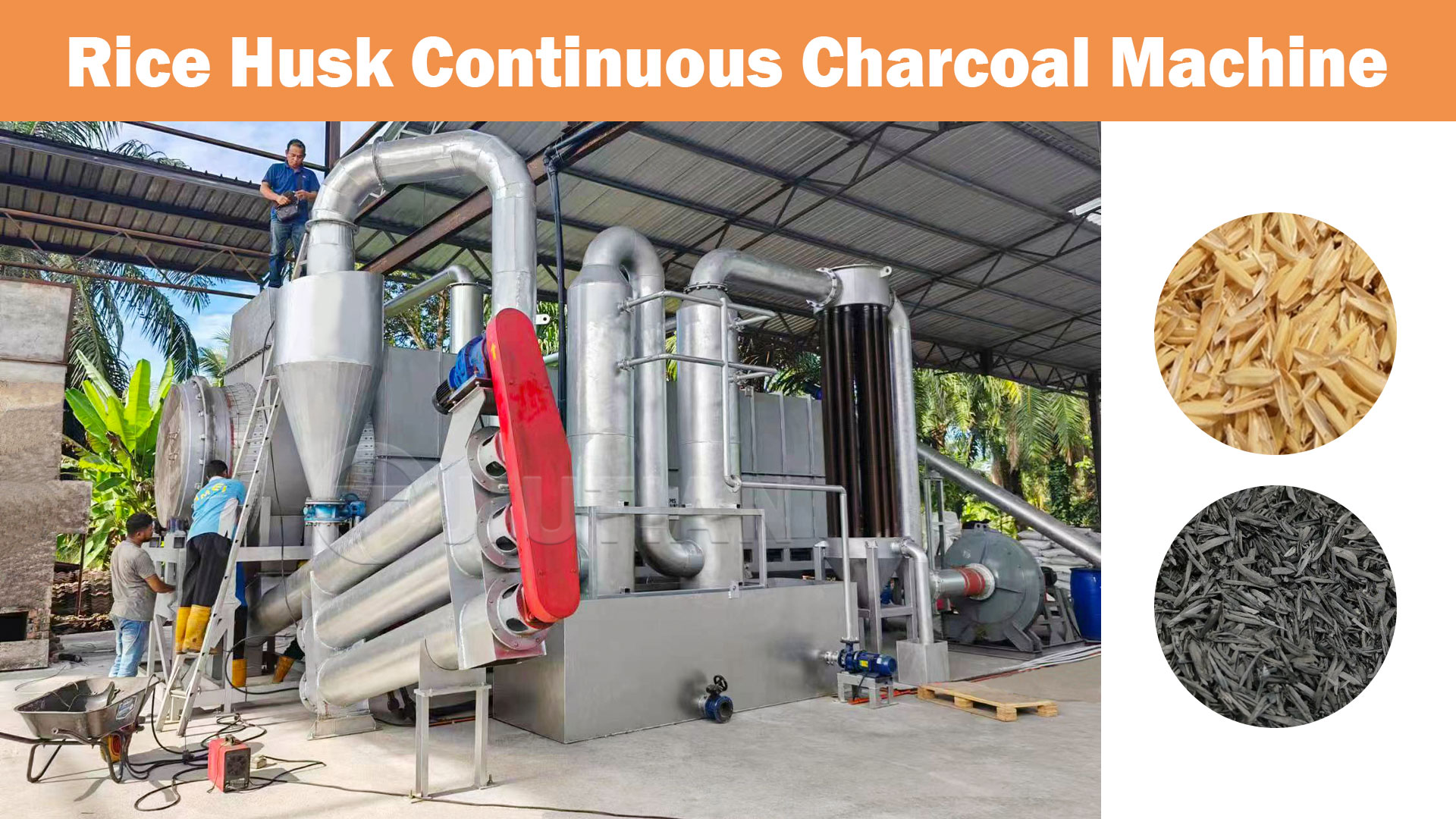

As a sustainable and cost-effective activated carbon material, rice husk activated carbon has gained increasing attention in various industries. Derived from agricultural waste, it offers unique benefits while facing certain limitations.

1.High Adsorption Capacity:Rice husk activated carbon possesses a porous structure with a large specific surface area, making it effective for adsorbing contaminants in water purification, air filtration, and industrial processes.Cost-Effective:Due to the low cost of raw materials and simplified processing (compared to palm shell activated carbon), rice husk activated carbon is more affordable, making it suitable for mid- to low-end markets.Renewable and Sustainable:As a biomass-derived material, rice husk activated carbon aligns with global sustainability goals, offering a greener alternative to non-renewable carbon sources.

2.Abundant Raw Material Supply:Rice husk is a byproduct of rice milling, generated in large quantities globally. This ensures a stable and low-cost raw material supply, reducing dependency on limited resources like palm shells or wood.Eco-Friendly Production:Utilizing rice husk reduces agricultural waste and promotes circular economy practices. The production process emits fewer pollutants compared to traditional activated carbon derived from fossil fuels.

3.Pre-Treatment Requirements:Rice husk contains high silica content, which requires additional pre-treatment (e.g., acid washing) to enhance porosity and adsorption performance. This adds complexity to the production process.Limited Micropore Volume:While effective for general adsorption, rice husk activated carbon may have fewer micropores compared to palm shell variants, reducing its efficacy in specialized applications requiring ultra-fine filtration.

4.Lower Calorific Value:Compared to palm shell activated carbon, rice husk has a lower calorific value, which may limit its efficiency in high-temperature applications or energy recovery processes.Variable Quality:The quality of rice husk activated carbon can vary depending on the source of rice husks and processing methods, potentially affecting consistency in industrial applications.

Rice husk activated carbon stands out for its sustainability, cost-effectiveness, and versatility, making it a promising material for industries prioritizing eco-friendly solutions. However, challenges such as variable quality, silica content, and lower calorific value must be addressed through optimized production techniques. contact Zhengzhou Jiutian Machinery Equipment Co., Ltd. Our engineers provide 24/7 guidance tailored to your production needs.