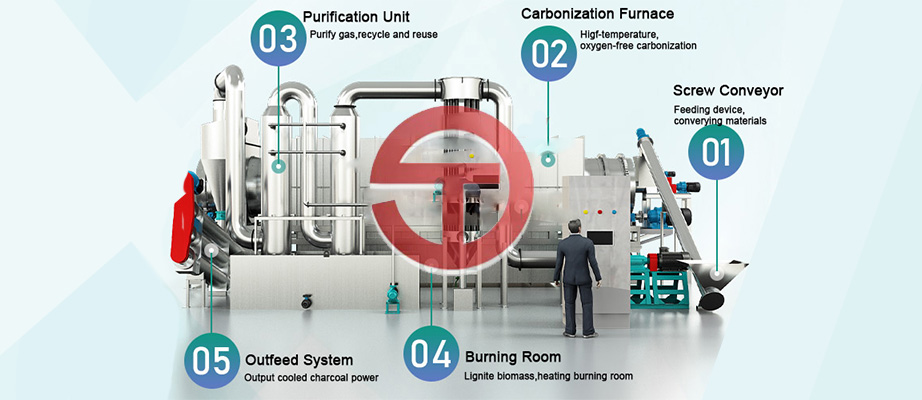

The carbonization machine is mainly composed of the following key parts:

一、Basic components

1. Gasifier: responsible for generating combustible gas and providing the necessary heat source for the carbonization process.

2. Flue gas purification system: used to treat the flue gas generated during the carbonization process to reduce environmental pollution. The system usually includes components such as smoke dust processor, combustible gas purifier, combustible gas condenser and induced draft fan.

3. Carbonization main system: It is the core part of the carbonization machine and is responsible for oxygen-free high-temperature carbonization of the material. Depending on the design, the carbonization main system may include the upper cracking chamber, the middle semi-cracking and semi-calcining chamber, and the lower calcining chamber.

4. Cooling system: used to cool the carbonized material for subsequent processing and storage.

二、Other auxiliary parts

1. Feeding and unloading system: responsible for feeding the material into the carbonization machine and discharging the material after carbonization is completed.

2. Drying main machine (some models): used to dry the material to ensure the smooth progress of the carbonization process. But there are also some new practical carbonization machines that do not require drying raw materials.

3. Transmission part and frame part: provide power and support for the operation of the carbonization machine.

4. Flue gas re-combustion device (some models): used to re-combust the purified flue gas to improve the utilization rate of thermal energy.

三、Special design part (for certain types of carbonization machines)

1. The continuous carbonization machine may also include frequency conversion induced draft fan, high temperature burner, feeder and discharger. These components work together to achieve continuous operation and efficient production of the carbonization machine.

2. Upper and lower double-layer multi-channel structure design: Some carbonization machines adopt this design to improve carbonization efficiency and product quality. This design usually includes drying part, flash layer, carbonization layer and other parts.

In summary, the components of the carbonization machine may vary depending on the model and purpose. But no matter what type of carbonization machine, its basic components include key parts such as gasification furnace, flue gas purification system, carbonization main system and cooling system. These parts work together to complete the carbonization process of the material.

If you need a carbonization machine, please contact us at any time! Zhengzhou Jiutian Machinery Equipment Co., Ltd. will serve you wholeheartedly!